Digital twin

be there in a second

At Offonshore, we provide advanced Digital Twin solutions designed to transform real-world assets into intelligent, interactive 3D environments.

By integrating cutting-edge 3D scanning technology with customizable features, our platform delivers immersive digital models tailored to your needs. As a result, you can visualize, manage, and maintain your operations more efficiently.

We serve a wide range of industries, including marine, offshore, oil & gas, real estate, hospitality, education, and healthcare.

Bring Your Spaces to Life

Next-Gen Precision with Digital Twins

From oil platforms and ships to industrial sites, Offonshore delivers next-gen Digital Twin solutions that bring real spaces to life.

We transform physical environments into interactive 3D models that are fully measurable, navigable, and easy to manage.

As a result, every asset, every room, and every detail becomes accessible from anywhere in the world.

51+

Across marine, offshore & industrial sectors

25+

With immersive 3D Digital Twin solutions

10+

Global Reach in 10+ Countries Supporting clients worldwide

1520+

For training, inspections & marketing

Different scanning options

Digital Training & Onboarding

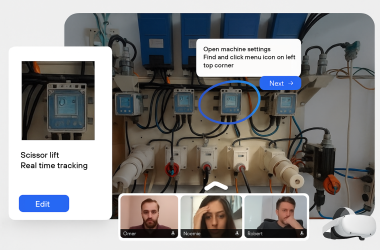

Our Connected Worker solution uses Digital Twin, AR, and VR to deliver immersive training experiences. Both remote and on-site teams

benefit from interactive modules that boost efficiency and reduce onboarding time.

Digital meeting

Step inside your virtual space. Users appear as avatars and walk through the model together—commenting, pointing, and deciding

collaboratively. As a result, meetings become

more productive—no screen sharing required.

IoT Integration

We connect your Digital Twin with real-time IoT data. This allows you to monitor equipment status, track energy use, and predict system failures—making every asset smarter and safer.

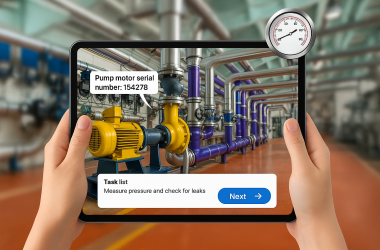

Augmented Reality (AR) Overlay

Use AR-enabled tablets or smartphones on-site

to access guidance, branding, or promotional content. For example, users can scan a storefront

or machine to reveal real-time data, product

offers, or feature instructions.

Measurement &

Accuracy Tools

Measure length, width, clearance, or space directly inside your digital model. These precision tools ensure every scan aligns with your layout and structural requirements.

Maintenance Planning & Scheduling

Assign recurring tasks, track service logs, and visually mark maintenance points in your Digital Twin. This enhances planning, reduces downtime, and improves operational transparency.

Analytics+

Gain Real Insights From Your Digital Twin

Track exactly where users click, move, and linger within your digital model. This heatmap-driven behavior tracking helps you understand which areas attract the most attention and which parts of your environment require more focus or improvement.Additionally, analytics tools can help identify weak points in training sessions or guide customer interaction strategies.

95% of our clients use Digital Twin analytics to improve operational performance

25% boost in efficiency reported through predictive behavior tracking

23x more customer engagement for businesses using data-informed environments

Applicable industries

Marine & Offshore

Monitor vessel conditions, track construction progress, and plan fleet maintenance with full digital transparency. Our Digital Twin technology supports vessel walk-throughs, refit planning, and safety training.Oil & Gas

Enhance HAZOP planning and improve safety with digital models of refineries, compressor stations, and pipeline terminals. As a result, training becomes safer and operations more efficient.Real Estate & Hospitality

Showcase properties remotely using interactive 3D models. Add branding, booking links, and customization features for a smarter guest experience.Retail, Events & Malls

Use AR pop-ups to deliver promotions and guidance. Vendors can place QR-tagged ads or interactively highlight zones inside a digital model.Public Infrastructure

Manage schools, hospitals, and government buildings with virtual replicas. Integrate IoT data to optimize daily operations and maintenance planning.Insurance

Create visual records of industrial and residential properties. Digital scans support documentation during underwriting, claims, or risk assessments.

Digital Twin Solutions

OffOnShore’s Digital Twin service is not just a scan — it’s a living platform for training, maintenance, managing, promoting, and transforming your real-world environments into future-ready spaces.

We Follow Best Practices

- Future-Ready Facilities

- Faster Decision Making

- Smart Integration

- Accurate to the Millimeter

Industry frequently asked questions

Digital Twin technology generates a virtual representation of physical objects, systems, or processes. When paired with enterprise and Internet of Things (IoT) data, Digital Twins offer the potential to gain insights, predict outcomes, access real-time data for decision-making, optimize processes, and enhance connectivity.

Unlike a rendered model derived from drawings, a visual twin like virtual plant offers a high-resolution photographic representation of the environment. This allows you to explore the actual site conditions as they exist, rather than the ‘as designed’ version, all while enjoying the advantages of seamless integration with CMMS and asset registers within the photographic environment.

The frequency of scans depends on the client’s requirements and the pace at which a facility undergoes changes. If needed, we can perform targeted rescans of specific areas or modules within the facility to incorporate the latest scenes into the existing environment, ensuring that scan dates are accurately tracked.

Due to it being web-based, all that is required is on-site Wi-Fi.

We recommend using tablet-sized or larger devices for the best user experience.

Absolutely! virtualplant provides a measuring tool within the program allowing you to measure spaces and calculate areas with ease.

We make every effort to capture as much information as possible during on-site scanning. While some items may be obstructed or missed, our images are captured in 4k resolution, enabling users to zoom in on most name plates for easy identification.

Moreover, virtualplant can be further enhanced with our automatic tag recognition add-on, which recognizes tags and matches them to your existing asset register, streamlining your asset management processes.

Typically, users can’t add information directly. However, when using our panel, an add-on that empowers contractors and internal teams, you can create standardized and error-free work orders with minimal training.

Absolutely, you can enhance your virtualplant model with various types of data. It’s possible to attach PDFs and images to asset tags, providing easy access to critical documentation. Additionally, external links (videos) to your asset register system can be included for seamless integration and organization of essential information.

virtualplant models are typically split into modules, rooms, or levels that correspond to the layout of your site. However, these spaces can be interconnected through navigation tags, allowing for a seamless transition and walkthrough through your facility.